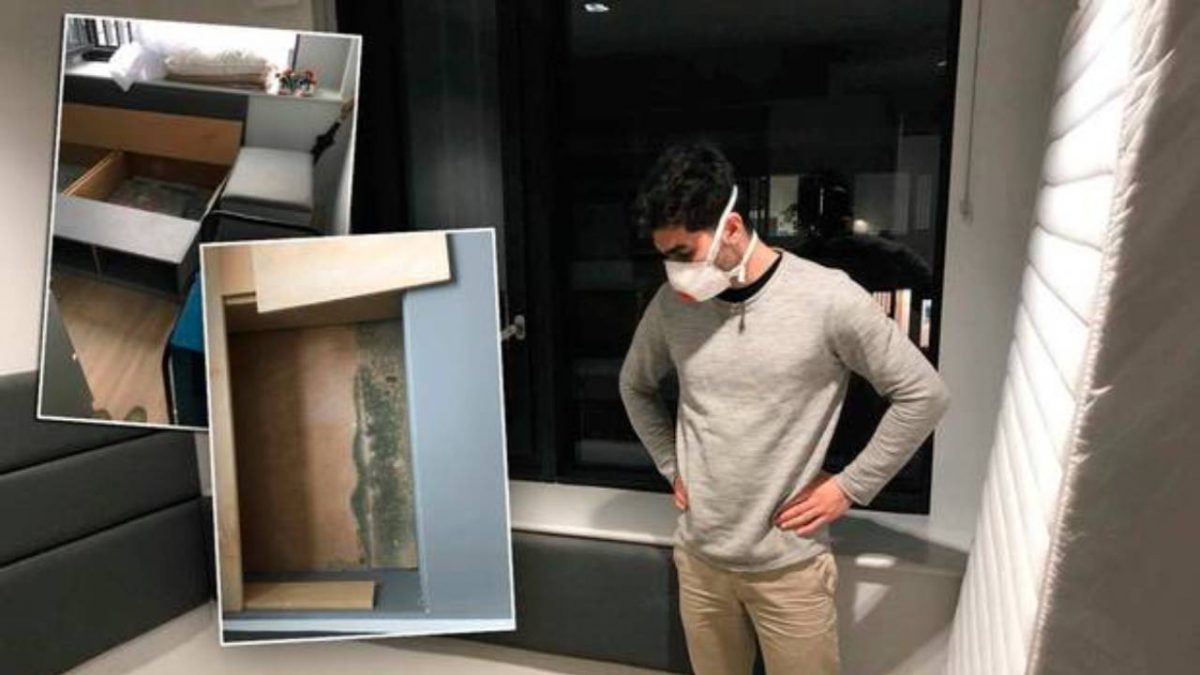

Health problems in ‘mouldy’ luxury student accommodation

According to Independent.ie

- Students describe mould in luxury student accommodation – at €1,000-a-month

- Duo say mould caused ill health: ‘My whole body was pulsating, my head, chest, stomach legs were throbbing’

- ‘It’s a total nightmare, this is supposed to be one the state-of-the-art student accommodation buildings’ – student

Understanding the Problem

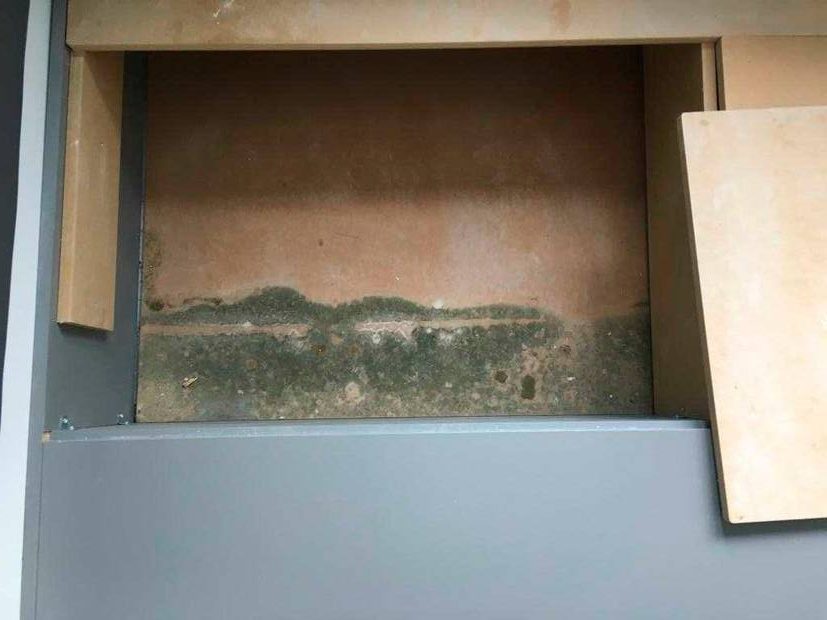

Indoor moulds typically are considered a problem when they are visible or when they are amplified or vary in species compared to outside air. Moulds generally need water, a food source and the right temperature range to grow.

Indoor environments contain a host of food sources, including drywall, carpeting, cardboard, paper, fabrics, wood and building furnishings. In addition, indoor environments are designed to maintain relative temperatures that are conducive to mould growth.

The best bet for controlling mold is to control, reduce or eliminate indoor moisture. Active fungal growth can cause building occupants discomfort and irritation, and it can increase the risk of respiratory illness.

Many people attempt to kill mould with fungicides, biocides and cleaners. This process will kill the mold, but it might not remove the problems. Leaving non-viable mould spores in indoor environments, especially in the HVAC system, might end up complicating indoor air quality complaints. So it is important for managers to develop and implement a pre-emptive plan to prevent mould growth in HVAC systems.

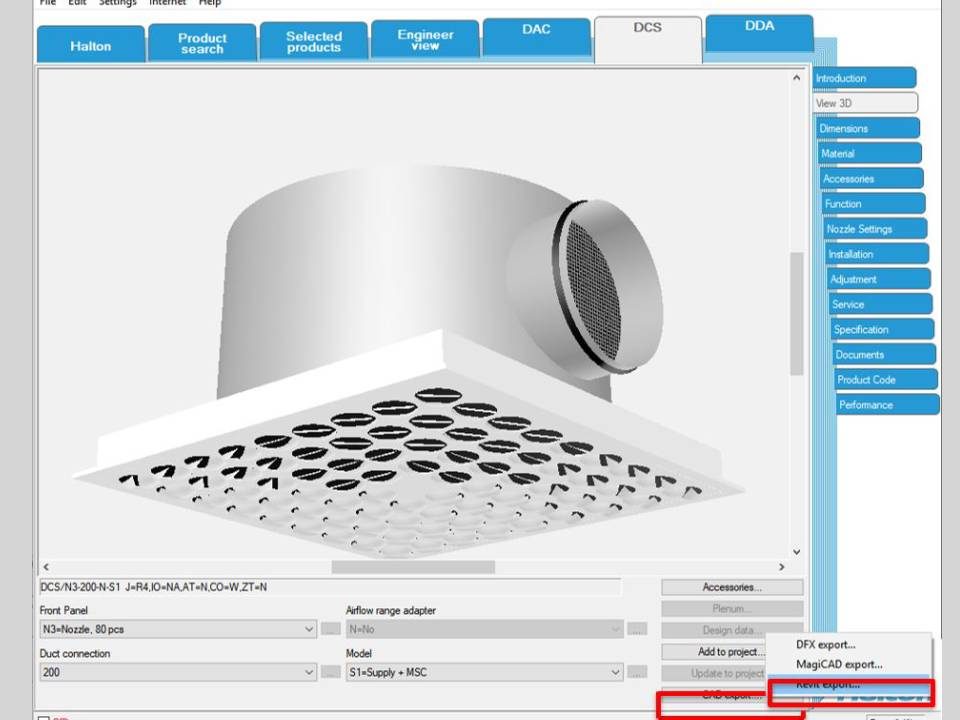

HVAC Systems: A Closer Look

The proper design, installation and maintenance of the facility HVAC system is essential for controlling indoor mould.

HVAC systems have a significant impact on condensation, a source of moisture for mould. The system can also transport mould spores between areas of a building. Poor design, operation and maintenance of the system also can provide moisture to support mould growth, and the system can provide a viable transportation mode for mould spores throughout a building.

Key components to check during an HVAC system assessment include these:

Coils and drain pans. Cooling coils dehumidify air and cause condensate water to drip into a drain pan and exit via a deep seal trap. Standing water accumulates if the drain pan is not properly designed and maintained, creating a microbial habitat. Proper sloping and frequent cleaning of drain pans is essential for healthy IAQ.

Humidification and dehumidification equipment. Technicians should drain and periodically treat wet surfaces as necessary to prevent microbial growth, and they should not allow duct linings to become moist from water spray.

Outdoor air dampers. Dust and debris that can support mould growth can obstruct screens and grilles. Cleaning these surfaces regularly can remove dust build-up.

Air filters. Technicians should replace filters regularly, either on the basis of pressure drop across the filter or on a scheduled basis. Technicians also should shut off fans when changing the filter to prevent contamination of the air. Filters should fit tightly in the filter housing.

Higher-efficiency filters are often recommended as a cost-effective means of improving Indoor Air Quality while minimizing energy use. Product specifiers should match filtration efficiency to equipment capabilities and expected airflows.

Ducts. A small amount of dust on duct surfaces is normal. Parts of the duct most susceptible to contamination include areas with restricted airflow, duct lining and areas subject to moisture or condensation. Technicians should identify and remediate excessively wet areas, including the system’s chronically damp internal lining. Technicians can prevent problems with biological pollutants in the duct work by:

- Minimizing dust and dirt build-up, especially during construction or renovation work

- Promptly repairing leaks and water damage

- Keeping key system components dry

- Cleaning coils and drip pans

- Performing proper filter maintenance

- Performing proper housekeeping in occupied spaces

Return-air plenum- Engineers often use the space above ceiling tiles a return-air plenum. Man-agers should strictly follow code that restricts material and supplies in the plenum to prevent contamination and insure an uninterrupted airflow. Workers also should remove all dirt and debris from construction activity.

Technicians must vigorously maintain all exhaust systems passing through the plenum to prevent leaks and prevent exhaust from being released into the plenum. Technicians also should check for condensation on pipes in plenum areas.

Cooling towers-Periodically monitoring water quality and chemical treatment to prevent microbial growth is essential for proper IAQ. Physical cleaning to prevent sediment accumulation and installation of drift eliminators also might be necessary.

Air intakes- HVAC technicians should pay attention to areas where outdoor air enters the HVAC system. they also should investigate accumulations of organic material in or near HVAC air intakes. Areas near dumpsters, garbage cans, boxes, paper, standing rain water, pond, lagoons, freshly distributed earth and vegetation can contribute to elevated indoor measurements of airborne fungal spores

These materials includes bird or bat droppings, which support the growth of pathogenic fungi and plant material that generally supports fungal growth. Ex-posure to pigeon droppings on window sills or air conditioning units in urban office buildings has been linked to fungal contamination.

The complex interior structures of commercial HVAC systems provide a host of reservoirs for moisture and mold growth. These areas are difficult to assess and remediate. Managers also can consider an assessment of:

- Filters for dampness, microbial growth and dirt

- Heat exchangers, such as the cooling coil section including drain pan

- Air conditioners for standing water, microbial growth and dirt

- Ductwork and air diffusers for dampness, microbial growth, dirt and rust.

Cooling coils are one example of a component that is difficult to inspect and thoroughly clean. Coil fins can buildup excessive mold growth, requiring the use of aggressive cleaners. Some cleaners, however, can cause damage to the coil fins.

High-pressure water spraying also can damage the fins. Improper cleaning can cause damage that affects the overall efficiency of the entire HVAC system.

Proper design, operation and maintenance of an HVAC system will go a long way to preventing or reducing mould issues. Understanding the HVAC components and conditions support mould growth, as well as steps that prevent mould growth in these areas, are essential information for managers looking to both prevent and remediate mould problems.