Design and supply of a new AHU Heat Recovery system in the UCD Science Building lecture theatre

Quick stats:

- SEAI did a case study on this project

- CO2 levels used to optimise ventilation efficiency

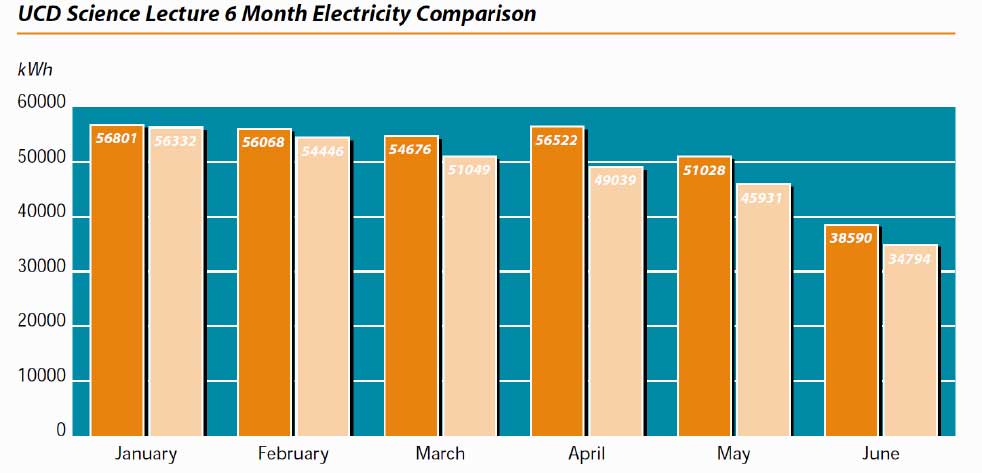

- Savings of 20,000 kWh in electricity and 106,000 kWh in heat

- Annual energy cost reduction of almost €5,000

- Reduced carbon dioxide emissions of 45 tonnes per annum.

- Simple payback on cost of additional energy saving features of 3 years.

- Reduced electrical load from 8.8kW to 0.64kW (93% reduction) when the AHU was on

These savings are largely attributable to the use of energy efficient ventilation plant and lighting in conjunction with occupancy based controls.

Challenges and Solutions

Challenge:

- Rising electricity consumption in the Science Lecture building leading to increased costs.

- Changes in occupancy patterns making it increasingly difficult to closely match plant schedules with lecture theatre occupancy.

Solutions

An AHU complete with efficient direct drive motors equipped with variable speed control and a thermal wheel which recovers heat from the extract air and supplies it to the incoming air was used.

Matching Ventilation Rates to Occupant Requirements

In order to optimise operation, and make full use of the variable speed drive, it was decided to regulate ventilation rates based on carbon dioxide (CO2) levels in the theatre. The CO2 sensor was placed in the extract airduct, and its reading was sent back to the BMS (Building Management System). The BMS regulates the AHU supply and extract fan speed to maintain CO2 levels below 600 parts per million (ppm).

System Performance

- The new ventilation system was found to:

- reduce plant operating time from 63.5 to 55.5 hours per week during term (12% reduction), with savings even greater when outside term time

- reduce ventilation rates from 6.7 m3 per second to an average of 0.84 m3 per second (87% reduction) when the AHU is on

- reduce electrical load from 8.8kW to 0.64kW (93% reduction) when the AHU is on

- reduce electrical energy consumed from 563kWh to 36kWh (94% reduction) per week during term

Thermal Performance

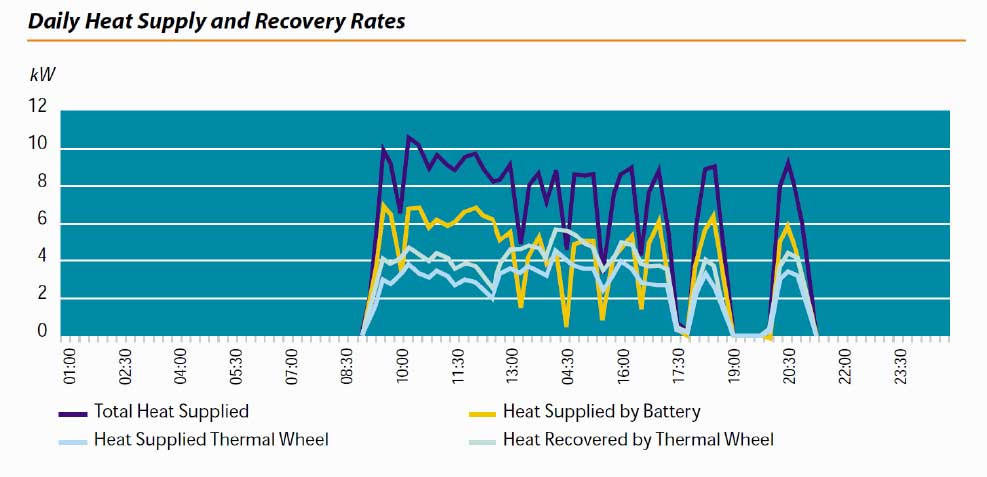

The reduction of 87% in ventilation rates has had a proportional effect on heating requirements. On the basis of system monitoring, it is estimated that lower ventilation rates have resulted in annual thermal energy savings of 100,000 kWh. Furthermore, the contribution of heat recovery by the thermal wheel has resulted in further savings of 6,000 kWh. The total value of thermal energy savings is €3,000 per annum. The chart below illustrates heat supply and recovery rates over the course of a day. The thermal wheel usually supplied between 30% and 50% of heat requirements.

Payback Analysis

Total Project Investment €78,200

Cost of additional energy saving features over standard costs €14,500

Value of annual electricity saving €1,900

Value of annual heat saving €3,000

Simple payback on total project investment 16.0 yrs

Simple payback on cost of additional energy saving features 3.0 yrs

Investment Rate of Return (20 year life) 34%