Data Centre Ventilation Systems

Entropic provide industry leading Ventilation and Air Conditioning System Solutions for Data Centres.

Our Air Handling Units are designed and manufactured to the highest quality to ensure even the most demanding design requirements are satisfied. We specialise in AHUs for all Data Centre applications, from Enterprise-level to Hyper-scale.

Our expertise and experience enables us to guarantee reliable performance with the highest levels of energy-efficiency, ease of installation, operation and maintenance. We pride ourselves in delivering the highest quality equipment, on-time and meeting all required quality standards.

Our experienced engineering team works closely with customers to design, supply and install the most suitable AHU’s for your data centre according to your unique job specifications and constraints.

Our modular AHU systems ensure efficient transport and ease of installation, with modules designed to optimise installation time, wiring, commissioning and maintenance and ensures we provide the most cost-effective solution.

In accordance with current travel restrictions and social distancing guidelines, we can provide Virtual Factory Acceptance Tests (FATs) to ensure the safety of customers and employees.

Why Choose an Entropic Data Centre Solution?

Efficiency

The combination of industry-leading energy recovery systems, latest motor technology and advanced thermal construction enables Entropic Air Handling Units to achieve world leading operational energy efficiency and optimal life cycle costs.

Custom-Built Design

Our specialist designers create unique solutions for each application according to customer requirements. Our next-generation design and simulation software enables seamless integration with the most modern Building Information Modelling software and Energy Simulation systems.

World Leading Partners

As part of our commitment to continuous improvement, we have partnered with world-leading product development laboratories, along with a global manufacturing and distribution network to achieve On Time, On Cost, On Quality solutions for Data Centres worldwide.

Software Download

To get detailed information about these products and systems, access our free AHU selection software where you can choose products to suit your project and export all technical product specifications to CAD and BIM designs. Click the link below for information and tutorials.

Data Centre Ventilation System Components

Our Data Centre Components are designed and selected to optimise operational efficiency, and to ensure ease of installation and maintenance. We provide fans and motors, filter units, heaters, coolers, humidifiers, dehumidifiers, silencers and heat recovery systems as part of our fully customisable Air Handling solutions.

Check out our full range of Data centre Ventilation products below.

Free Cooling Dampers

USS External Louvre

- Steel external louvre for intake and exhaust air

- Grille design prevents rain, snow, leaf and animal ingress

- Polyester-painted galvanised steel as standard

AHU System Components

Fans and Motors

- Low energy, low vibration, low noise fans

- EC motors for highest efficiency for variable speed

- Direct Drive and Belt Driven available

Silencers

- Low turbulence frame for minimum fan energy consumption

- Abrasion proof up to 20m/s

- Vertically arranged mineral fibreboard panels.

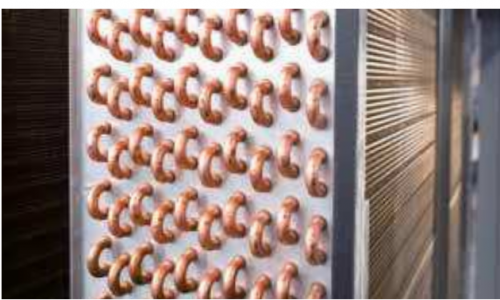

Heaters and Coolers

- Optimised designs for Free Cooling, Heat Recovery, DX, Chilled and Hot Water.

- Seamless copper pipes with integrally moulded aluminium fins.

- Long-life Corrosion-protected frames for all climate conditions.

- Large variety of material and construction options to ensure tailored solutions.

Rotary Heat Exchanger

- Heat recovery with an efficiency of up to 90%

- Storage mass made of alternating smooth and corrugated aluminium foil

- An adjustable felt seal between rotor and housing

- Separation from rotor diameter 2500mm

Diagonal Flow Plate heat Exchanger

- Heat recovery with an efficiency of up to 80%

- Corrosion-resistant aluminium or epoxy resin coating

- Bypass dampers for summer and to prevent freezing

HYDROOPT Circuit Compound Systems

- Circuit compound system with over 80% efficiency of heat recovery

- Piping unit for connection of supply and exhaust air heat exchanger can demonstrably be cleaned down to the core

Humidifiers

Selection of Energy Efficient Humidification Solutions

- High-pressure water spray humidifiers

- Circulating water system (CWS) or freshwater system (FWS)

- Vapour humidifier (steam)

Cooling Systems

- All systems piped, wired and tested at factory

- Pre-configured for optimum automation

- Refrigerant Systems suitable for Dual Cooling/Heat-pump operation

Weatherproof Design

- Corrosion resistant intake chamber

- Integrated weatherproof louvres with Multi-leaf dampers

- Materials selected for all climate conditions

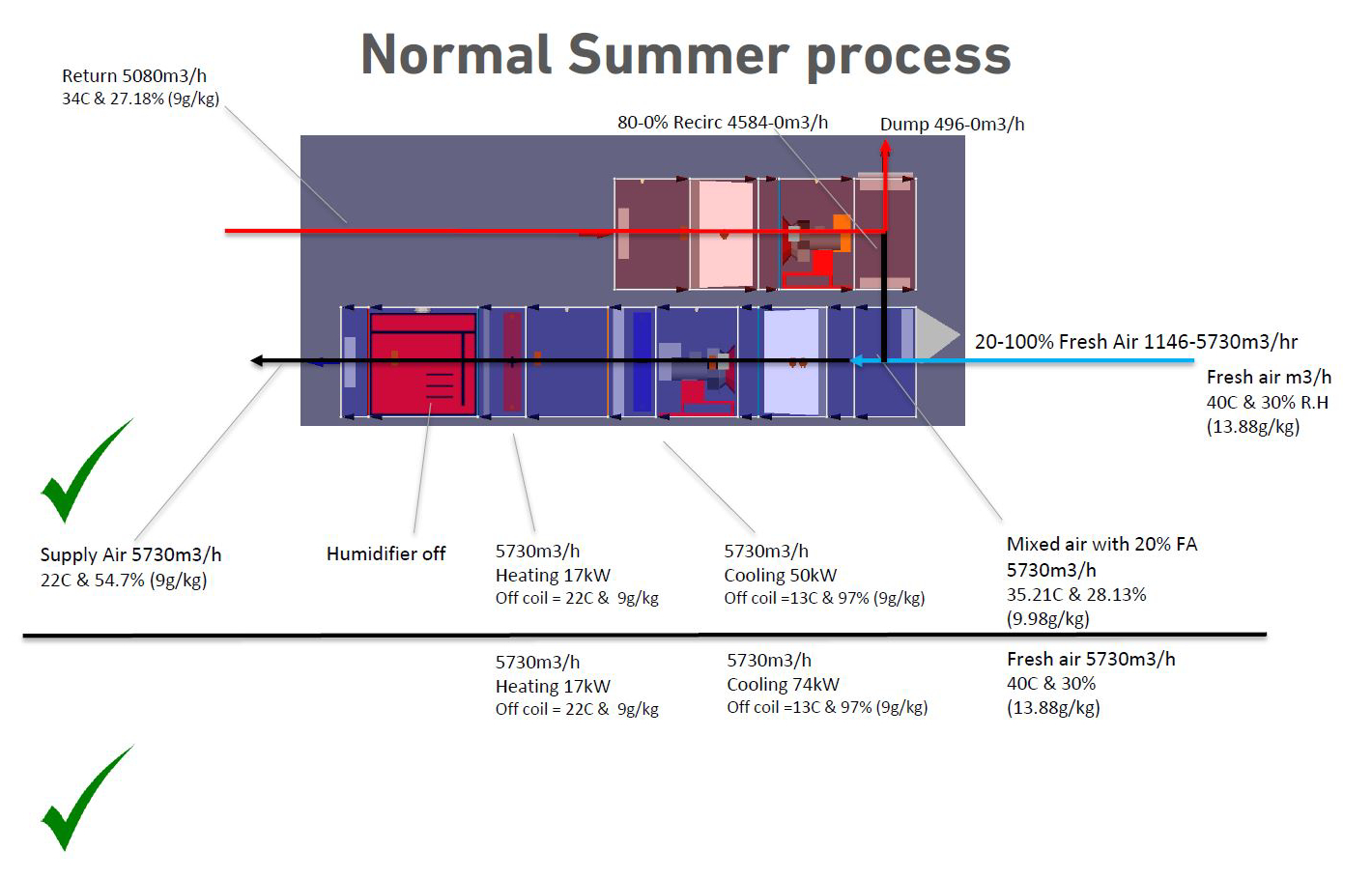

AHU Design for CRAC Systems

With CRAC units in the space, the fresh air needs to be conditioned.

Case Studies

Check our Data Centre case studies by clicking on the button below.

Contact Us

We realise Data Centre projects require speedy solutions and revisions to bring the design to a close. Entropic can assist you in achieving a quick cost-effective engineered solution, if you have any queries or need help from one of our experienced Engineers please contact us.