Heat Transfer in a Chilled Beam Room System

Heat Transfer in a Chilled Beam Room System

Chilled beam systems are primarily used for cooling and ventilation in spaces, where requirement for good quality environmental conditions and individual space control is needed and where the internal moisture loads are moderate. Systems can also be used for heating in some applications. One or more active chilled beams installed in the space are connected to the ventilation; cold water and if required low pressure hot water systems.

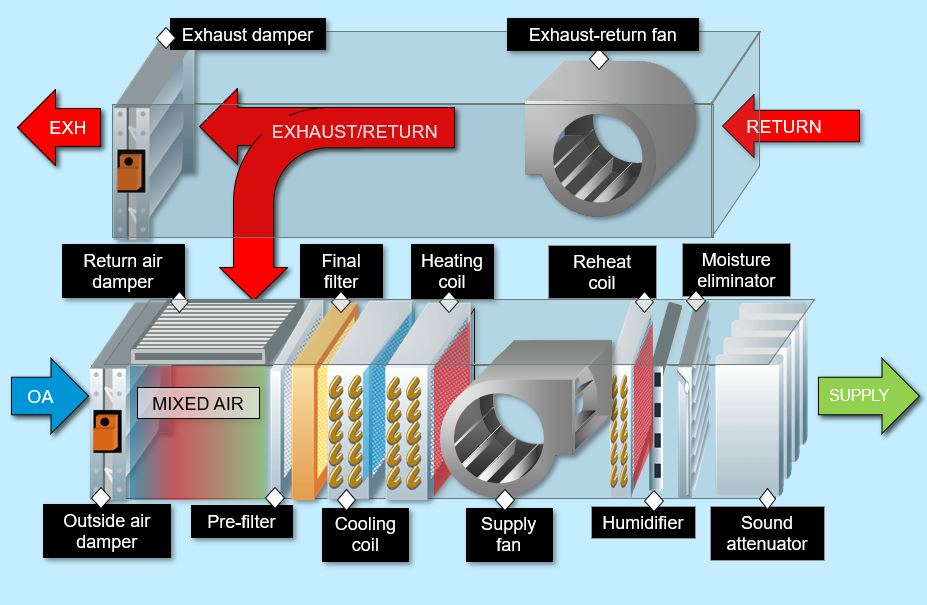

The main air-handling unit supplies primary air via distribution ductwork into the various rooms through the chilled beam. Delivery of the primary air induces room air to recirculate through the beam’s heat exchanger. The heat exchanger cycles either cold (60-70 OF or 16-20 OC) or warm (90-110 OF or 30-45 OC) water, thus cooling or warming the room air. Recirculated room air and primary air mix prior to supply into the space. Regulating the flow of water through the beam’s heat exchanger controls room temperature.

Passive chilled beams includes only a heat exchanger for cooling and if required for heating. The operation is based on natural convection of room air through the heat exchanger. The primary air is supplied to the space using separate diffusers either in the ceiling or through raised floor.

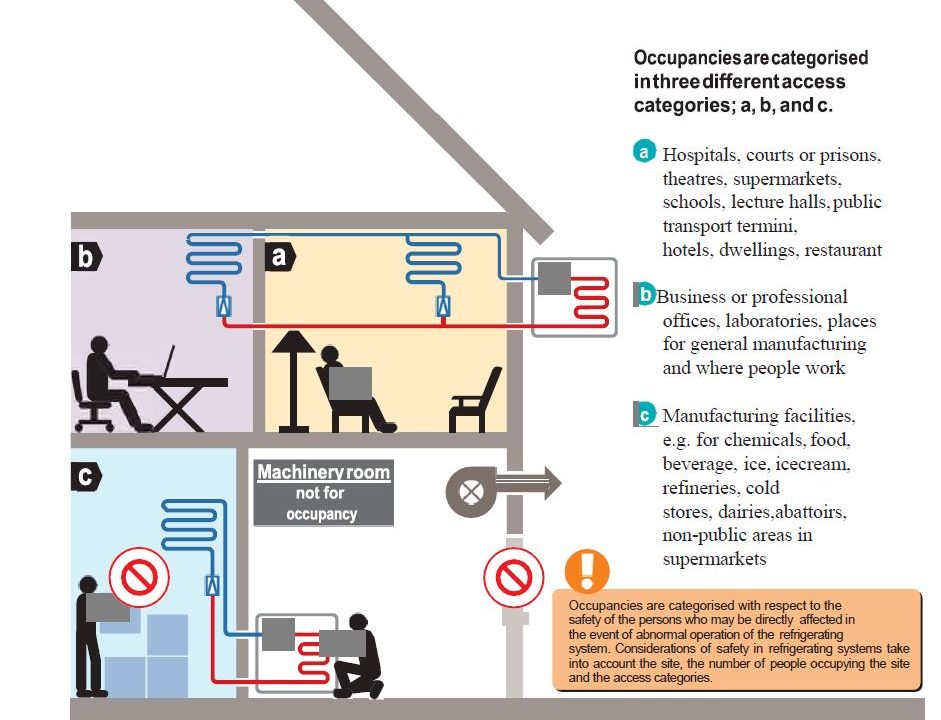

Typical applications for beam systems are: cellular and open plans offices, hotel rooms, ward rooms in hospitals, retail and banks either in exposed installation or integrated into a suspended ceiling. Due to dry coil operation, the beam system should be used in spaces where the internal moisture loads are moderate, the primary air is dehumidified and infiltration through the structures is in control.

Chilled beam system promotes excellent thermal comfort and the energy and space saving advantages, which the use of water as a cooling medium provides. The system operation is simple and trouble-free, with limited maintenance requirements. Beam system design complements the flexible use of available space, whilst the high temperature cooling and low temperature heating maximize the opportunity for free cooling and heating.

Full air systems are often a better choice in spaces where the primary airflow requirement is high, like conference areas, meeting rooms and classrooms. The variable air volume (VAV) is recommended if heat and contaminant loads are varying according the occupancy. Also the spaces, where internal moisture loads are high or there is an increased risk of infiltration e.g. through open doors, the full air systems or wet operating cooling systems (e.g. fan coils) are recommended.

Energy Efficiency of Chilled Beam System

Use of chilled ceilings and beams has a positive effect on energy consumption on buildings. Since water is used as an energy carrier instead of air, the system is using energy more efficiently. It is also possible to improve energy generation efficiency due to high temperature cooling and low temperature heating. Also the sustainable energy sources (waist heat, ground heat etc.) and free cooling is easier to use.

Chilled Beam Operation

Factors affecting the cooling capacity

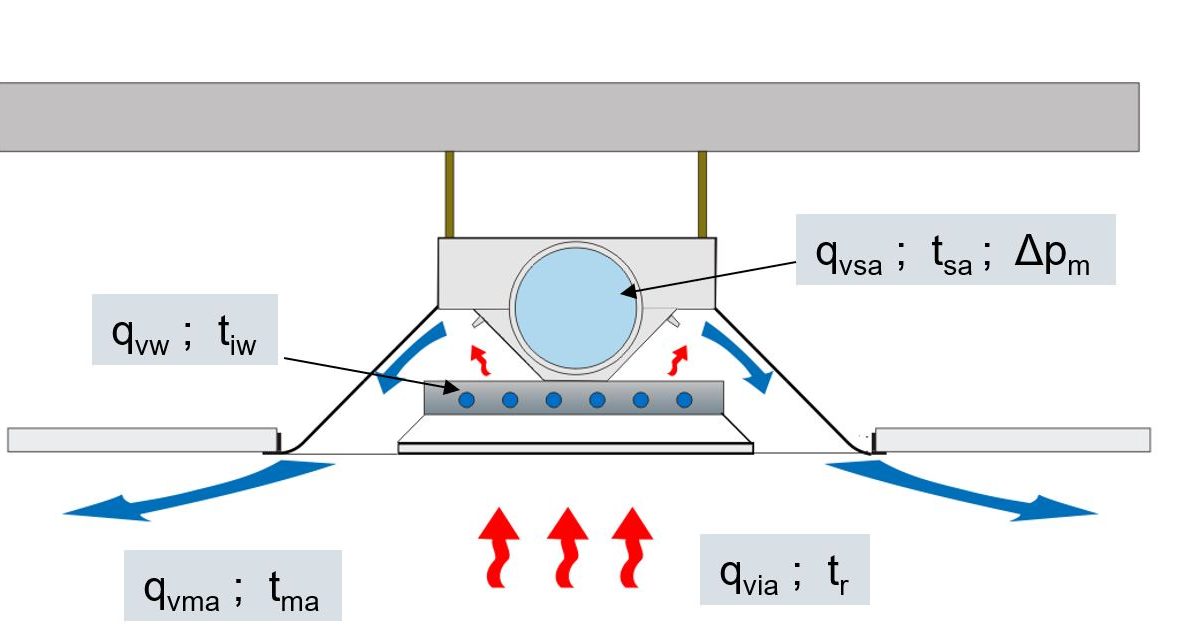

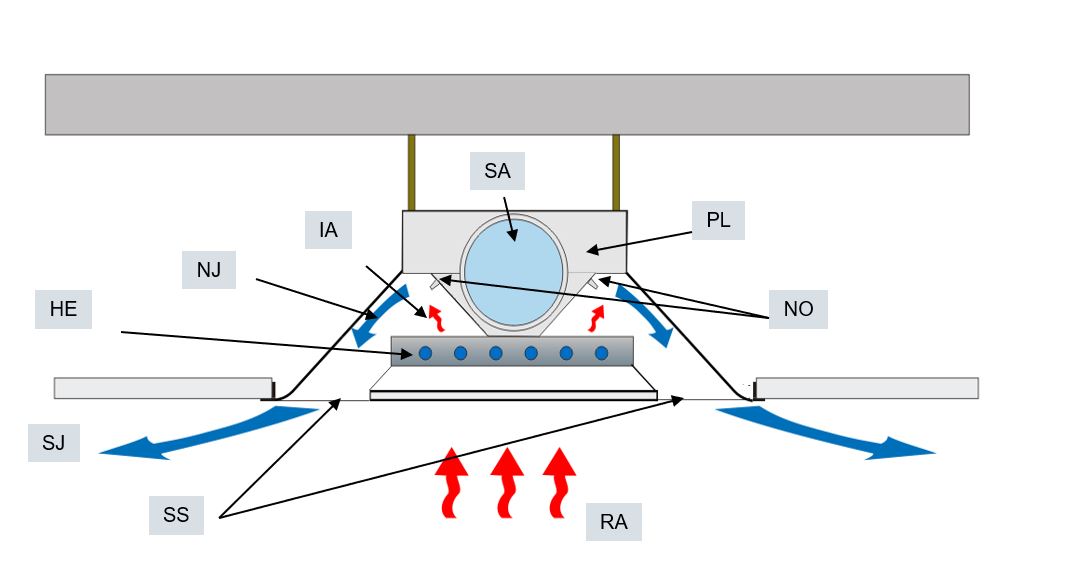

The primary supply air (SA) enters the plenum ( PL) of the active chilled beam. From there it is diffused into the room through nozzles (NO) and supply slots (SS) located at the bottom of the beam.

The supply air nozzle jets (NJ) efficiently induce ambient room air (RA). The induced air (IA) flows through the heat exchanger (HE), where it is either cooled or heated.

The mixed supply air jet (SJ) is directed horizontally along the ceiling surface.

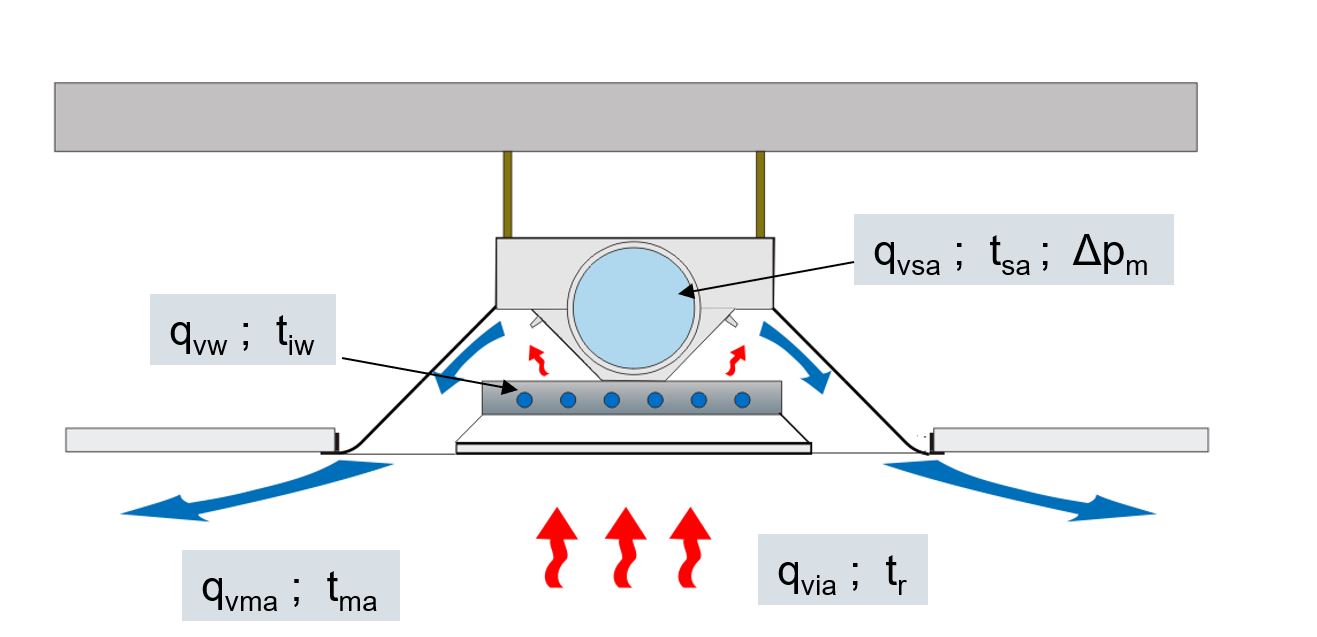

Chilled Beam Operation Parameters

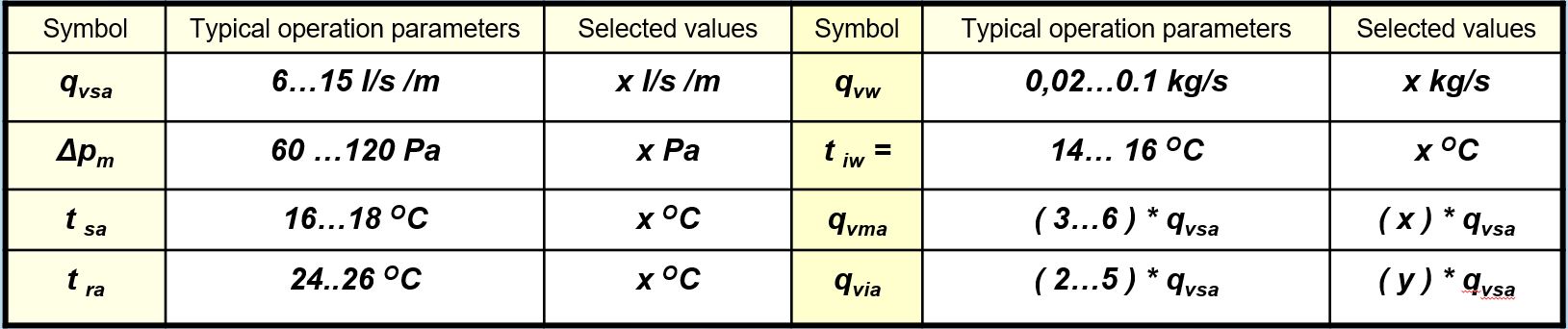

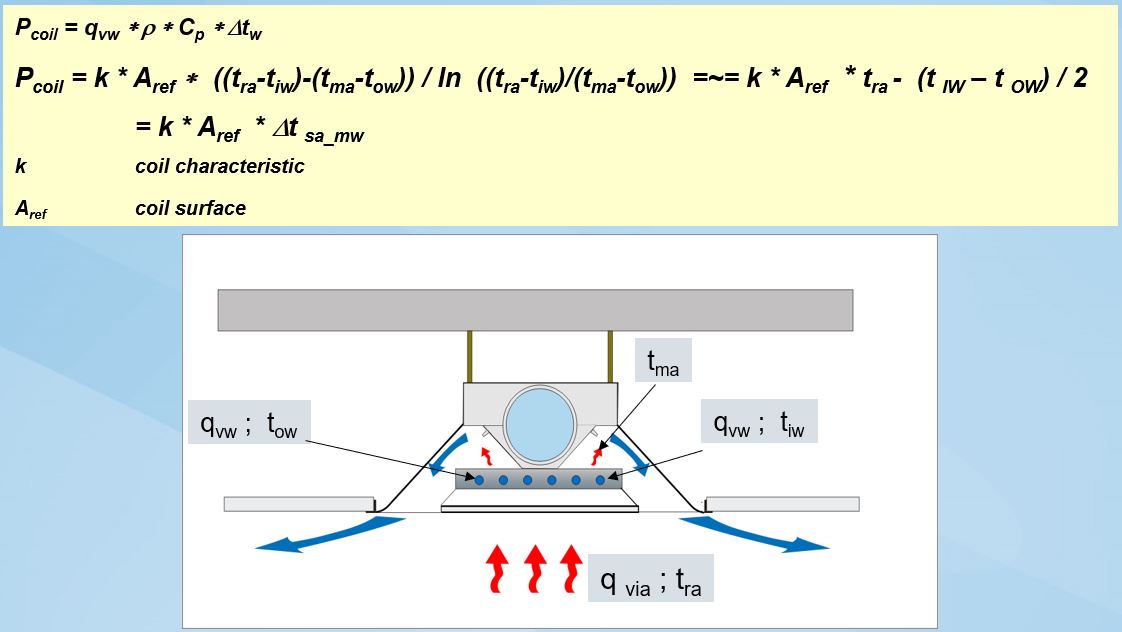

Heat is transferred from the space to the cool primary supply air and to the chilled water in the cooling coil.

Heat is transferred from the space to the cool primary supply air and to the chilled water in the cooling coil.

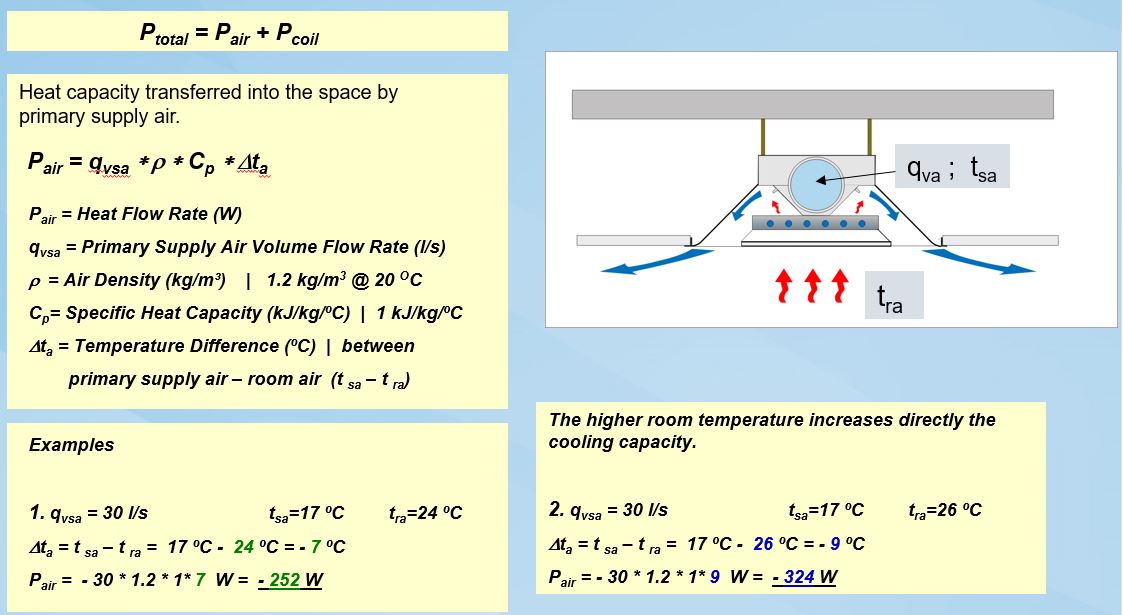

Heat is transferred from the space to the chilled water into the space in the cooling coil

Heat is transferred from the space to the chilled water into the space in the cooling coil

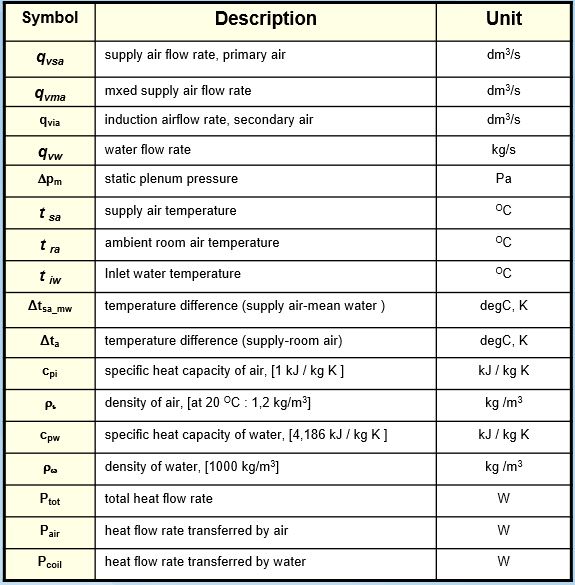

Notation

Heating design with active chilled beams

Design of heating system is started by defining the required heating capacity of the system. In traditional heating systems the design is often based on high safety margins to make sure that building is warm enough in all cases. When chilled beam system is used for heating, the over sizing of the heating system is fatal for proper system operation. Higher the heating capacity of unit is, more difficult is to get warm air in high level to mix to the colder room air.

Chilled beam heating capacity is 8 – 16 Btu/h ft2,floor (25 – 50 W/m2,floor), which is typically enough in a well insulated and tight building. If the heating inlet water temperature is higher than a. 113 OF (45 OC), secondary air is often too warm and do not mix properly with the room air (Fig. 4). The relatively low temperature gradient in the space increases the air temperature near the floor and improves the comfort in the space as well as increases the energy efficiency of system (decreases the short circuit and thus the exhaust air temperature).

The mixing is also depending on the window surface temperature and height. Higher and colder the window is, colder the air falling to the floor is, and temperature gradient between secondary air and room air becomes bigger. This is why it is recommended to use beams for heating only when windows are good enough (surface temperature is higher than a. 57 OF / 14 OC).

Active beams heating capacity is depending on the primary airflow rate. This is why the output of heating system is clearly decreased when ventilation is shut off during the nighttime. This is why the open active beams should be specified to meet the heating requirement without ventilation. Active closed beams do not perform at all without ventilation due to its closed construction and this is why the closed beams can be used for heating only when ventilation is operating 24 hours per day.