Different types of chilled beams

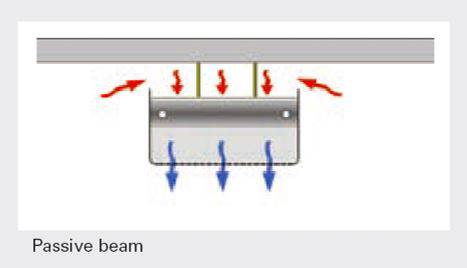

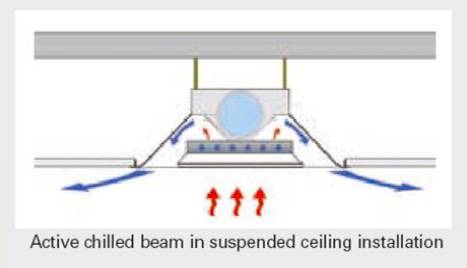

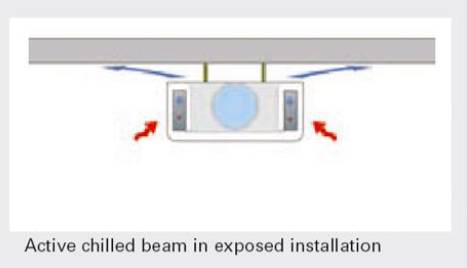

A chilled beam is an air distribution device with an integral coil that may be installed within a space in the buildings in order to provide sensible cooling and heating.

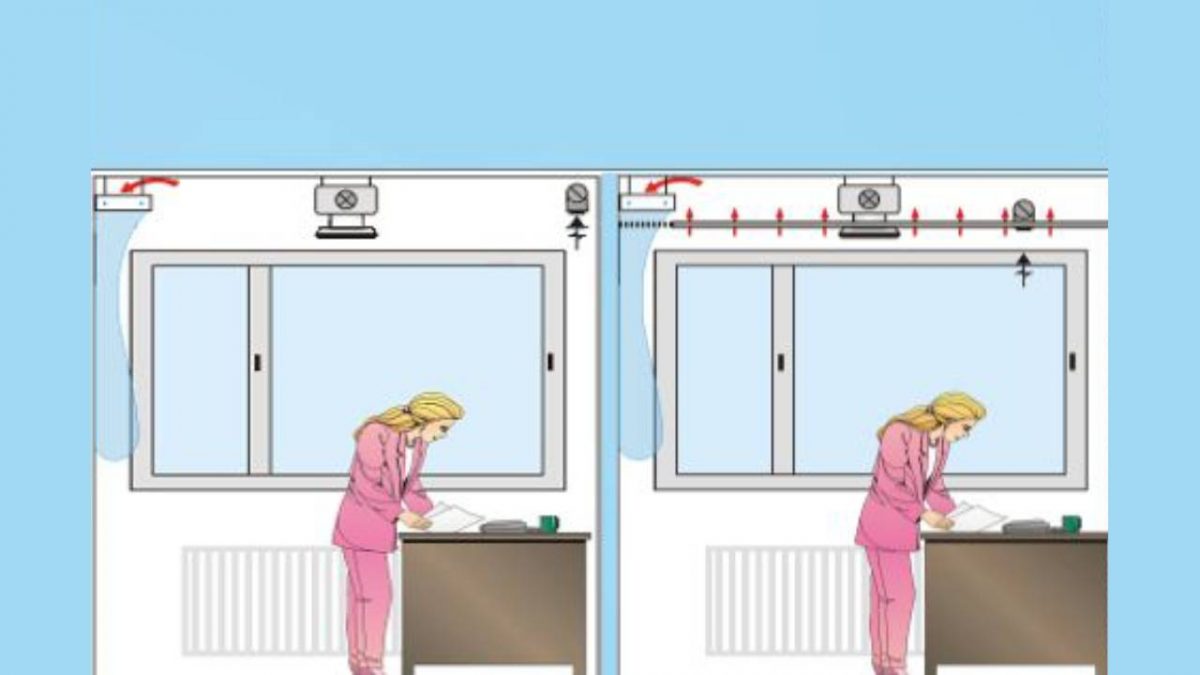

Cooling only Passive Beam Applications

- No Fresh air supplied through beams -Libraries

- Beams are simply finned coils containing cold water – Shops

- Often used in conjunction with displacement – Atriums

- No control on air flow patterns in the room – Corridors

- Lower levels of occupant comfort

- Higher risk of draughts

- Not to be located directly over occupants

- Heating & Cooling

- 4 Pipe System

- Ducted Fresh Air

Benefits of using Chilled Beams

- No Fans

- Low energy consumption

- No Draughts

- 14°C water does not overcool air

- No fan –low air velocities

- Uniform Temperatures

- Small vertical temp gradient

- Well mixed airflow

- Easy installation

- Flexible layouts

- No noise

- No fan breakdowns

- No fan electrical consumption

- No fan maintenance

- No Filters

- No filter maintenance

- No Condensation

- No wet coil

- No condensate drains

- No condensate leaks

Chilled Beams in Office Environment

Typical customer needs and requirements

- Satisfied users

- Energy efficiency

- Cost efficiency

- Flexibility

- Ease of use

Solution:

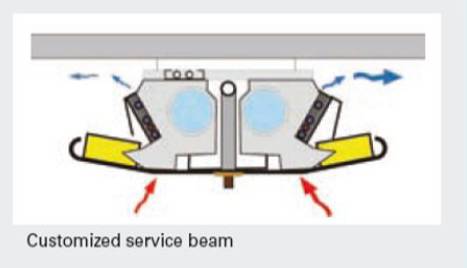

- Adaptable products: one product several applications

- Optimised indoor climate management

- Adaptable, energy efficient system design

Benefits of Halton Indoors Office Solutions

- Individually adjustable indoor conditions

- Optimised life cycle costs

- In-built flexibility for fast and cost efficient changes

Energy Efficiency of Chilled Beam System

- Eliminates numerous small fans in fan-coils throughout building

- Increased inlet water temperature in cooling (14 OC or above)

- Improved chiller efficiency (Significantly higher COP)

- Easier to use free energy sources and heat pumps (Dry Coolers, Aquifer etc)

- Decreased inlet water temperature in heating (35…40 OC)

- Full, minimum fresh air system, typically:

- Small ducts

- Small AHU

- Lower duct pressure than in traditional induction units