Objective definition of comfort ISO 7730 EN 15251

Advantages

- Objective, engineered, concrete definition of quality and thermal comfort

- Protection for the specifier

- Recognises impossible to satisfy everyone due to individual differences

- Greater comfort achievable with greater investment

Can we define quality objectively?

- ISO 7730

- What is Thermal Comfort?

- 6 Factors affecting Thermal Comfort

- Objective Measurements of Comfort – PMV and PPD

- EN 15251

- Designing for Thermal Comfort – simulation software

- Products

- Post-occupancy evaluation

ISO 7730

- Defines thermal comfort

- Describes 6 factors that control it

- Provides standard models to quantify it

EN 15251

- Design and sizing of ventilation system and other building systems

- Comfort and energy efficiency

Contents

- Can we define quality objectively?

- ISO 7730

- What is Thermal Comfort?

- 6 Factors affecting Thermal Comfort

- Objective Measurements of Comfort – PMV and PPD

- EN 15251

- Designing for Thermal Comfort – simulation software

- Products

- Post-occupancy evaluation

What is Thermal Comfort?

‘that condition of mind which expresses satisfaction with the thermal environment’ ISO 7730

6 Factors affecting Thermal Comfort

Environmental Factors

1.Air temperature (K)

2.Radiant temperature (K)

3.Air velocity (m/s)

4.Humidity (%)

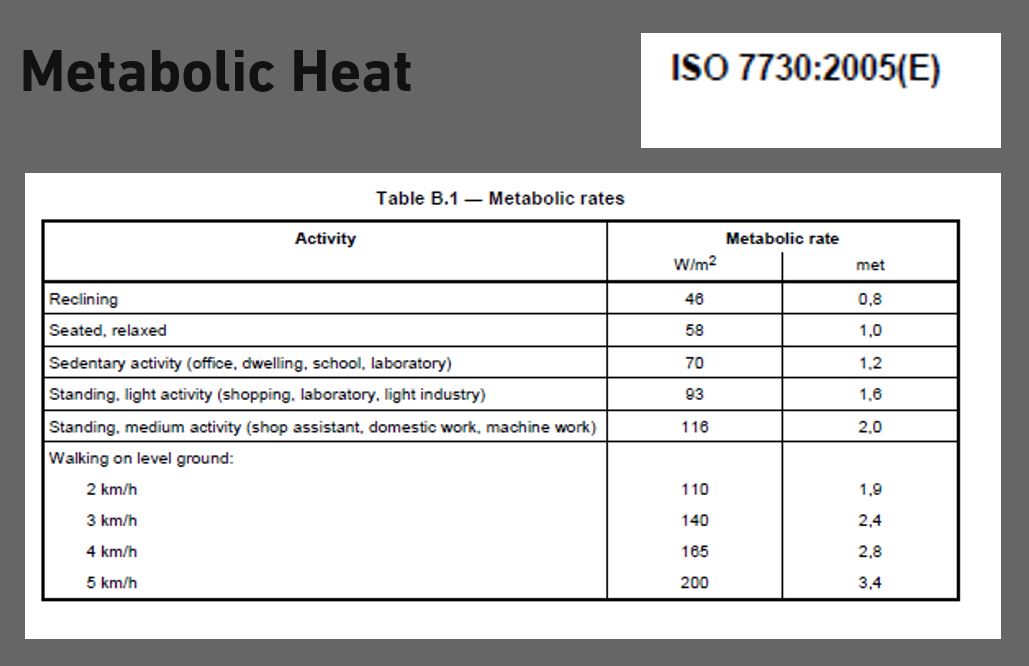

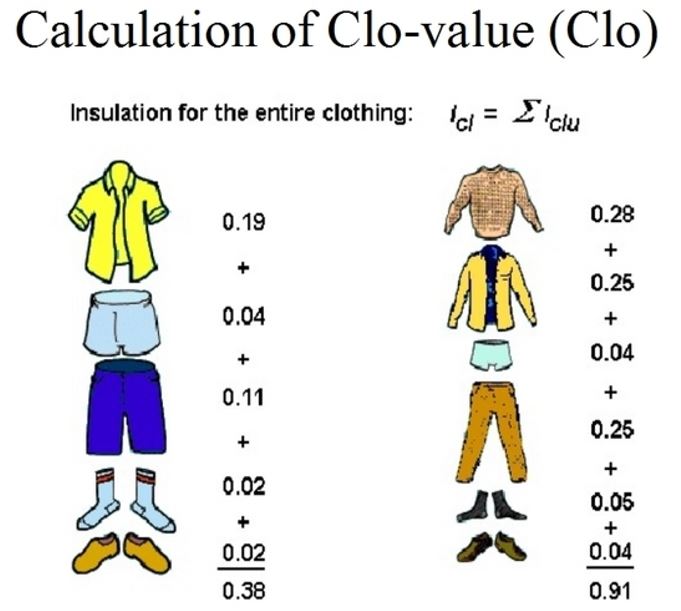

Personal Factors:

5.Clothing insulation (clo or K.m2/W)

6.Metabolic heat (Met or W/m2)

6 Factors affecting Thermal Comfort

- Air temperature

- Temperature of air around human body

- Dry bulb temperature

- Measured using standard thermometer or temperature probe

- 22°C – 26°C optimum

- Motivation and performance significantly affected

- Radiant temperature

- Measured with black globe thermometer

- Greater influence than Tair

- Skin ~ black object

- Sources: the sun, fires, hot surfaces, ovens, radiant panels

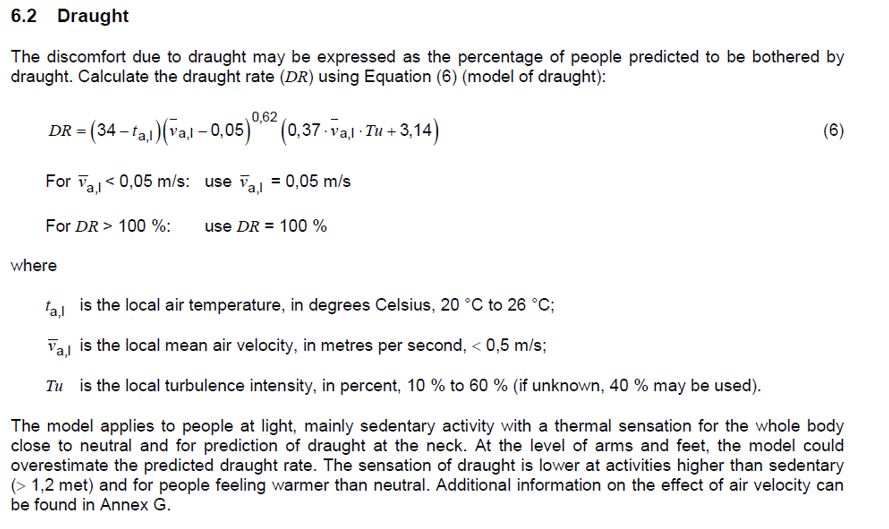

- Air velocity

- Varies over time

- Human sensitivity

- Too low -> stagnant air with odour

- Too high -> draught

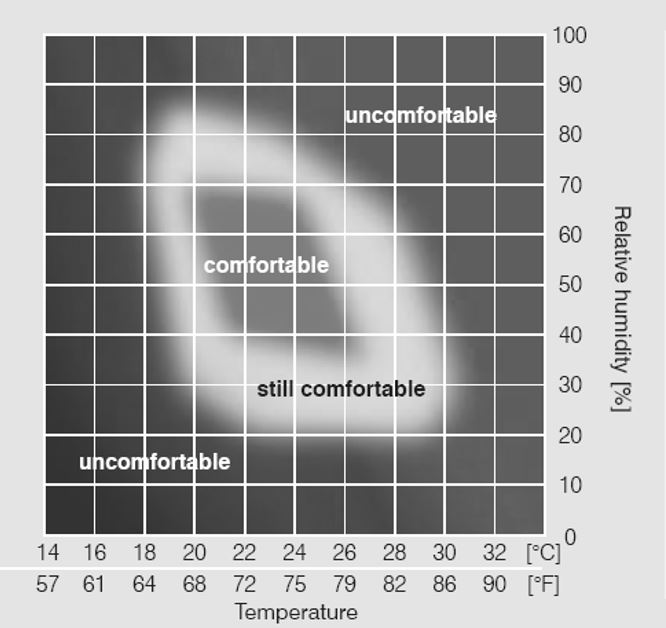

- Humidity

- Relative Humidity (RH): 40-70% – no major impact on thermal comfort

- High humidity prevents cooling through perspiration

2 Personal Factors:

- Clothing insulation and metabolic heat

- Variable

- Sample values in ISO 7730

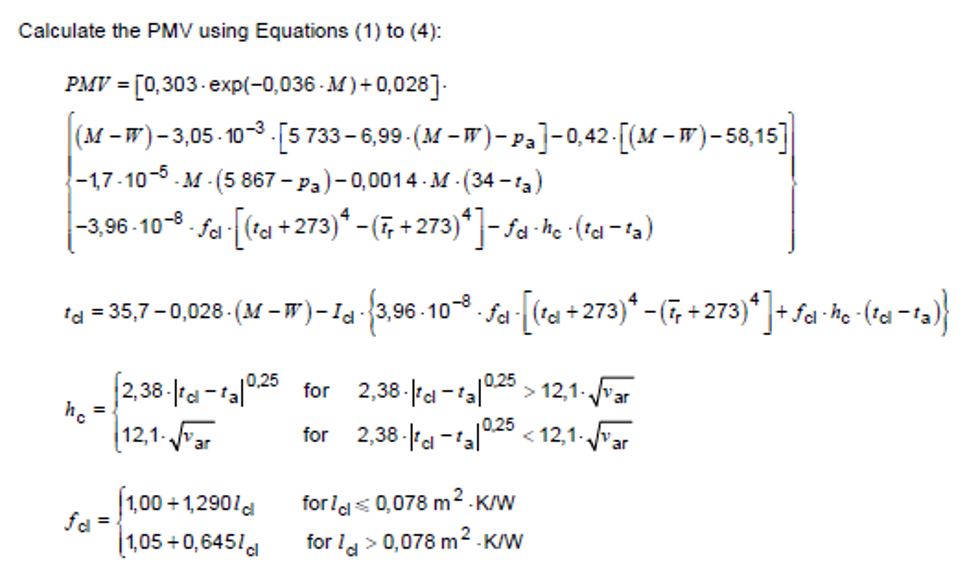

PMV

- Equations developed based on surveys of occupants in tightly controlled environment

- Enter room characteristics related to 6 factors

- Predicts mean occupant rating of room

- Zero = Thermal neutrality (ideal)

- Decreasing quality at extremes

- First objective means to define quality

Calculate PMV

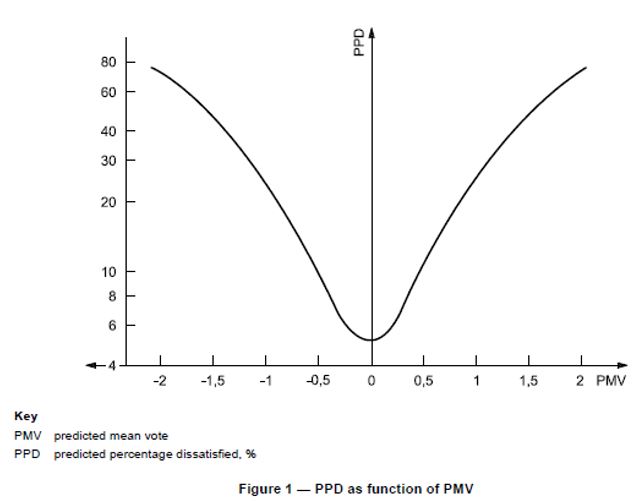

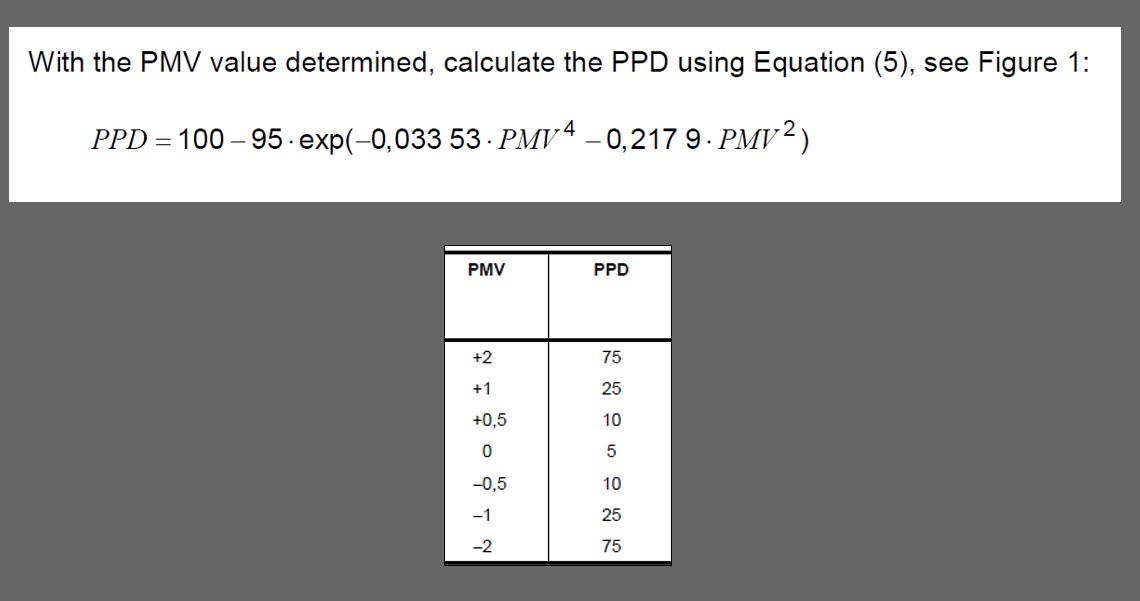

PPD

- Percentage people dissatisfied

- Equation to relate PMV to PPD

- Second objective means to define quality

- ASHRAE 55 requires at least 80% of occupants to be satisfied

Calculate PPD

ISO 7730 – Draught Rating

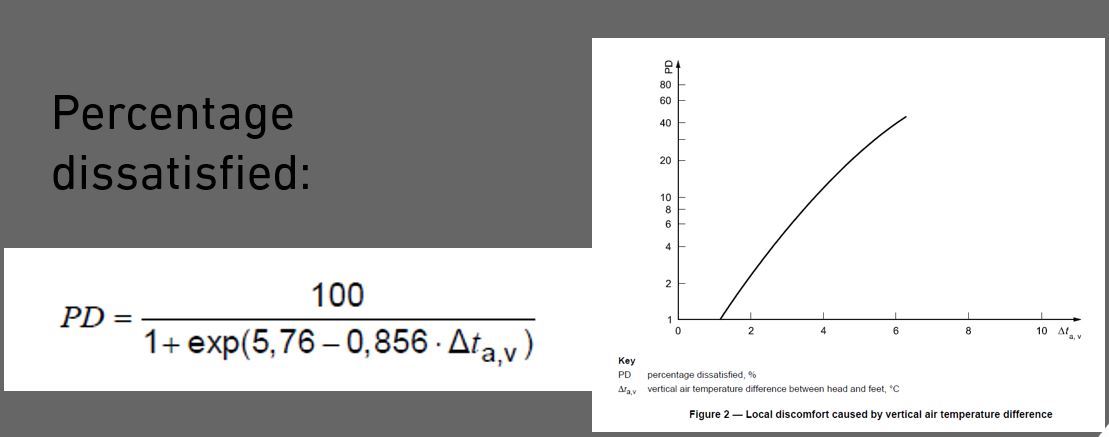

ISO 7730 – Vertical air

temperature difference

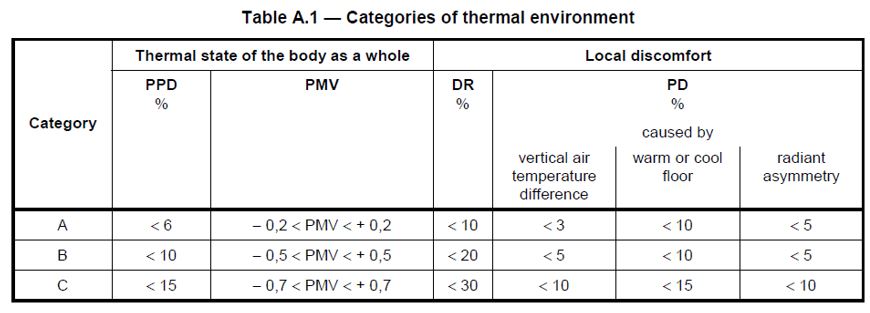

Acceptable thermal environments for comfort:

- 3 categories of environment defined

Specifying using EN 7730

1.Value of PMV or

2.PPD or

3.Category (A/B/C)

Specifying using EN 7730

Advantages

- Objective, engineered, concrete definition of quality and thermal comfort

- Protection for the specifier

- Recognises impossible to satisfy everyone due to individual differences

- Greater comfort achievable with greater investment

Contents

- Can we define quality objectively?

- ISO 7730

- What is Thermal Comfort?

- 6 Factors affecting Thermal Comfort

- Objective Measurements of Comfort – PMV and PPD

- EN 15251

- Designing for Thermal Comfort – simulation software

- Products

- Post-occupancy evaluation

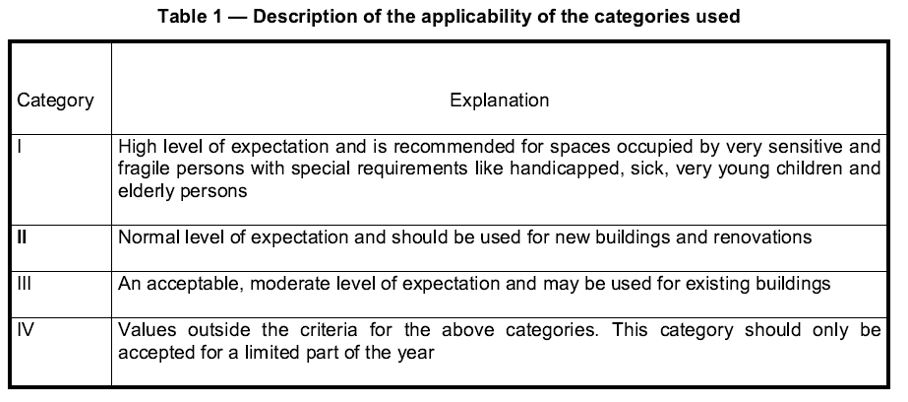

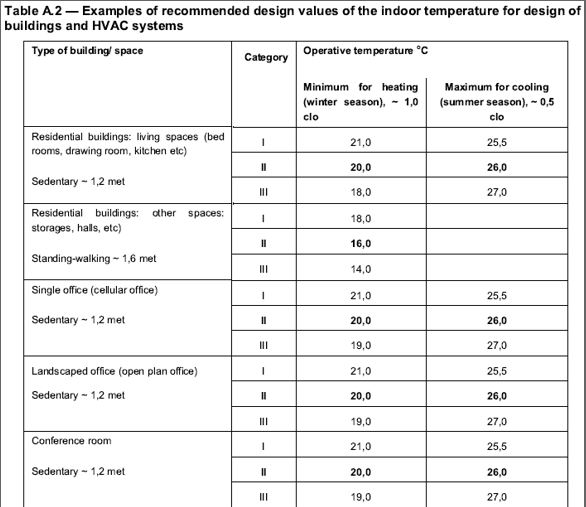

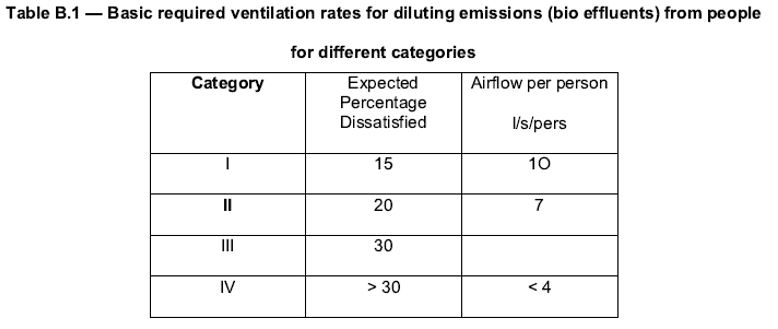

EN 15251

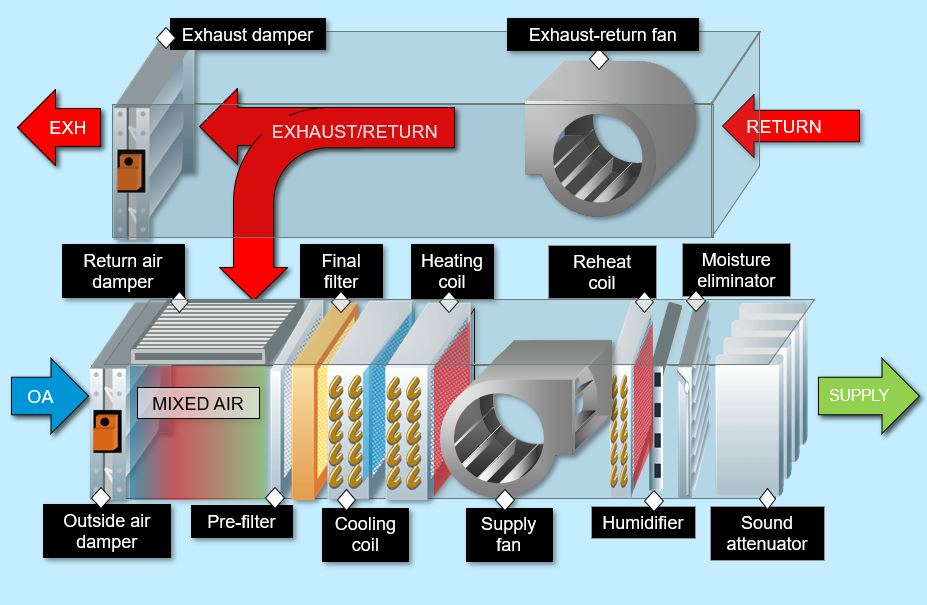

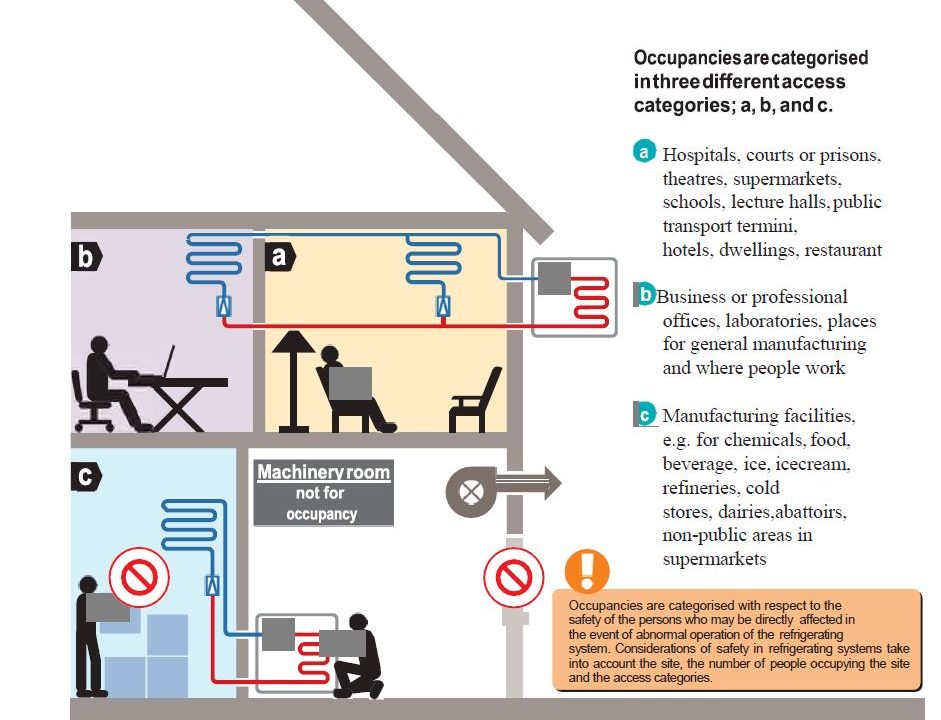

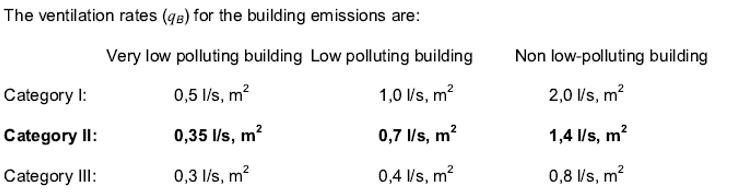

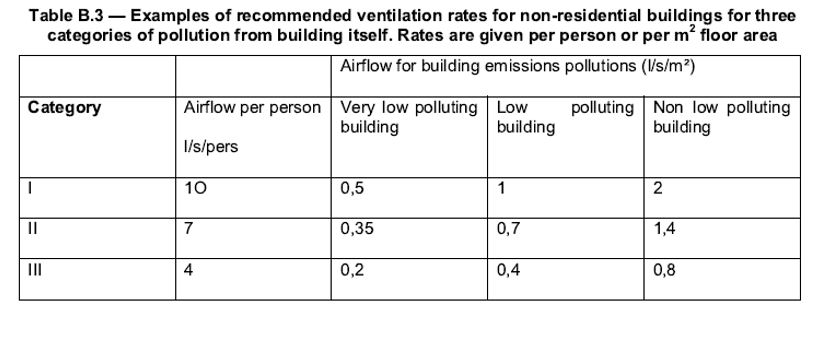

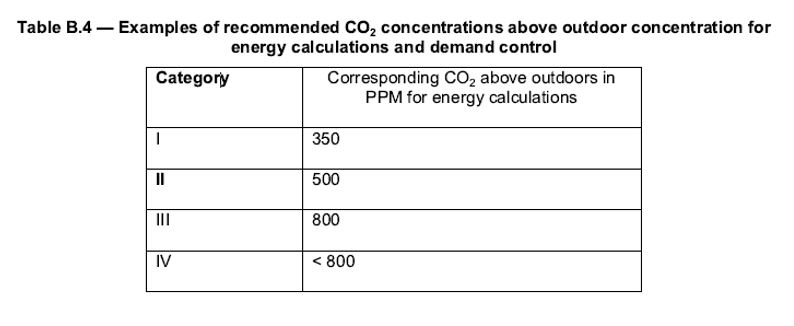

Design Input Criteria for HVAC System Dimensioning

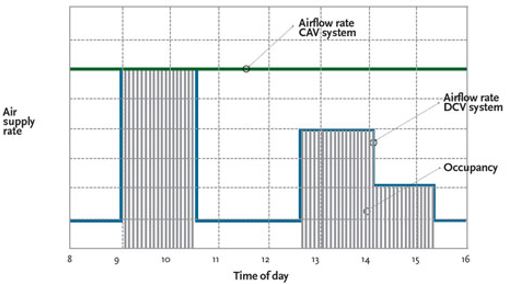

Demand-controlled Ventilation (VAV)

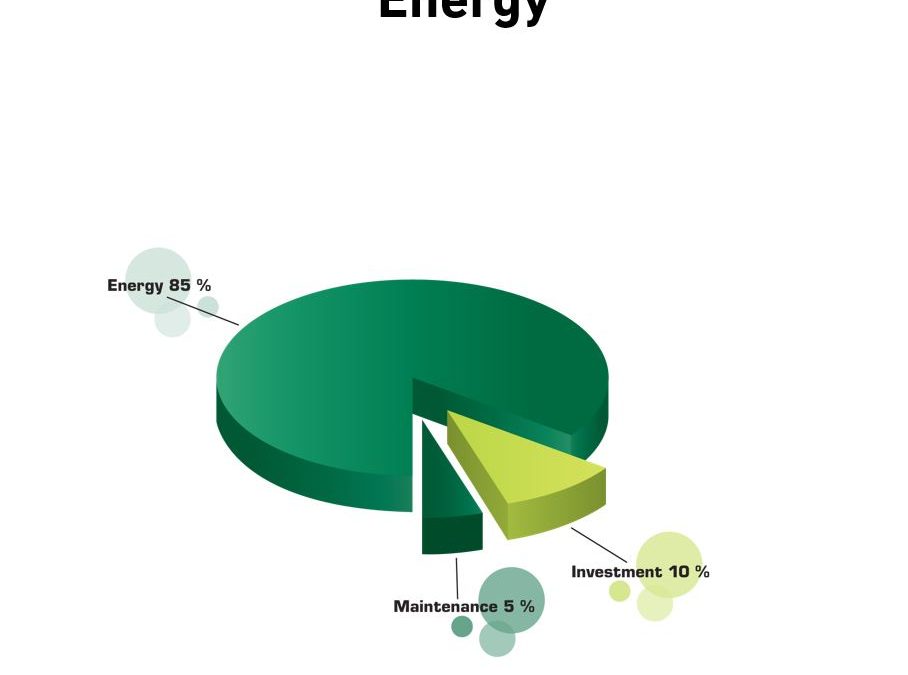

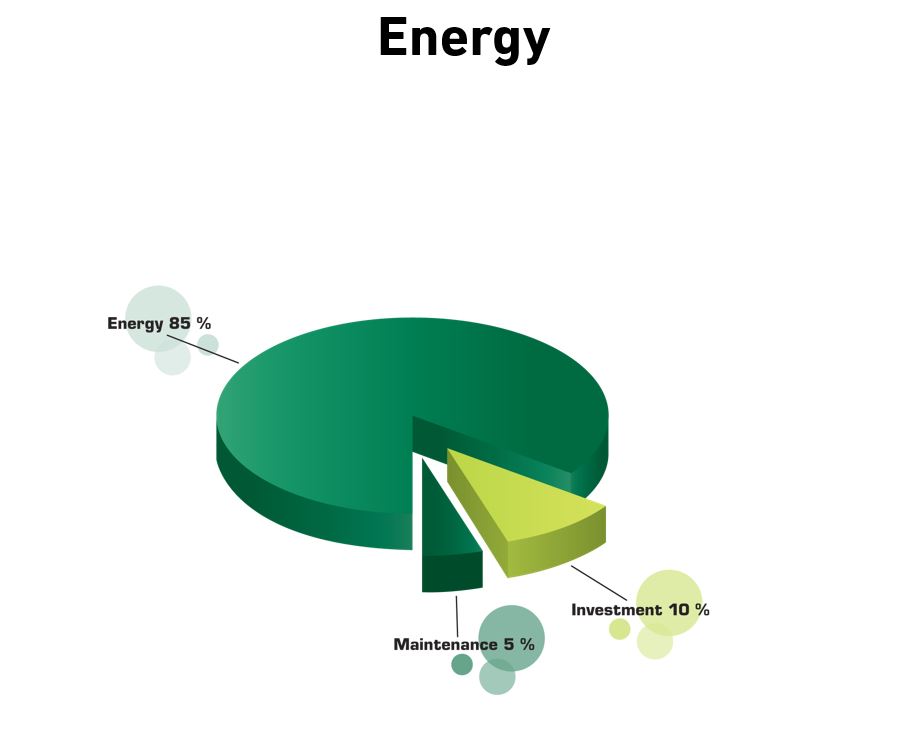

Reduce Fan Energy Use

Meeting Rooms/Conference Rooms/Lecture Theatres

PIR/CO2 Sensors

Design Input Criteria for HVAC System Dimensioning

Humidity

- Small effect on thermal sensation and perceived air quality

- High = microbial growth

- Low = dryness and irritation

- Requirements influence dehumidifying (cooling) load

- Special requirements for buildings such as museums, historical buildings, etc

Related posts

November 26, 2019